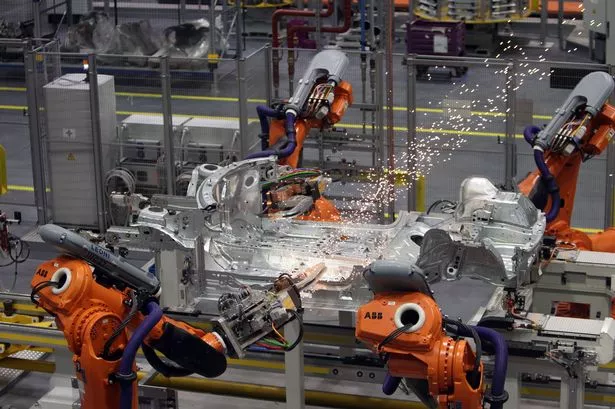

Government told to back North West manufacturing as it bounces back from economic crises

North West manufacturing output has grown by a quarter in the past decade and seen one of the UK's strongest post-pandemic bounces, a new report has shown. The Make UK/BDO Annual Regional Manufacturing Outlook shows that since 2013 output in the region has increased by 26%, while output in 2023 was 12% above the pre-pandemic levels recorded in 2019. Make UK says the new government now needs to back the sector with a new industrial strategy to ensure that growth can continue. READ MORE: First North West firm wins backing from £660m Northern Powerhouse Investment Fund The Make UK/BDO report showed manufacturing accounts for almost 15% of the region’s total output (13.4%), well above the national average. It accounts for 330,000 skilled jobs, amounting to almost 10% of the region’s workforce. The biggest sectors are transport - largely aerospace and automotive - followed by food & drink, and chemicals. In 2023 the North West accounted for almost 10% of the UK’s total manufacturing exports with the EU being the dominant destination (50%), followed by the USA (17%) and Asia & Oceania (17%). Dawn Huntrod, region director for Make UK in the North said: “Industry remains critical to the growth of the economy, providing high value, high skill jobs and aiding the process of creating wealth across the UK. “The new Government has made a welcome bold statement of its intent to tackle the UK’s anaemic growth at national and regional level. It should now back this with a radical, cross government, long-term industrial strategy which has the need to tackle the UK’s skills crisis at its heart. This should be allied with the local growth strategies and priorities of each region, including infrastructure and innovation, together with other measures to ensure the UK is now fully open for business.” Graham Ellis, head of manufacturing at BDO in the North West added: “The North West is the second largest region in the UK, in terms of GVA, with the manufacturing sector playing a critical role in the region’s output. “Over the last few years, manufacturers across the region have faced multiple external shocks and changing policy priorities. They have shown great resilience in overcoming these challenges. “There is now an exciting opportunity for the sector to work with the new government on the development of a new long-term industrial strategy. This could unlock vital investment needed across the North West to continue to bolster manufacturing output and skilled employment opportunities so crucial to the regional economy.”

County Durham's Cook Defence Systems sees rising revenues and profits

A North East defence specialist has seen a 30% increase in turnover, triggered by global geopolitical instability increasing demand for armoured vehicles. Cook Defence Systems, in Stanhope, County Durham, is a world-leading designer and manufacturer of track systems for armoured vehicles and a strategic supplier to the Ministry of Defence, as the only British manufacturer of tracks for the Army’s tanks and armoured vehicles. The wider sixth-generation family firm William Cook Group, which has its headquarters in Sheffield, produces components for the rail, defence and energy sectors and its site in Stanhope, County Durham, is the main site for its defence operations, as the home for its businesses Cook Defence Systems, William Cook Stanhope and William Cook Intermodal. For the year to July 1 2023. Cook Defence Systems saw turnover jump 30% from £23.6m to £30.8m, while operating profit and pre-tax profit almost doubled from £1.17m to £2.25m. Total comprehensive income for the period was £1.84m, more than the double the £830,938 posted a year earlier. Company secretary Michael Hodgson highlighted how the company had seen demand for its products jump on the back of the Ukraine conflict. In the accounts report he said: “During the period under review, the nature of the company’s business activities has continued to be the design, sale and distribution of track systems and associated items for armoured vehicles. Whilst the global trading environment remains generally difficult, particularly in terms of energy markets, the Ukraine conflict has provided great impetus to our defence business and thanks to our significant investment programme over several past years, the company and the group are well equipped to meet this additional demand. “The outbreak of conflict in the Ukraine in the early part of 2022 created unprecedented issues across many areas of the global economy, not least in the energy markets. The directors have continued to deploy a prudent hedging policy that has offered some protection against the volatile and increasing market prices. “In addition, our long-standing relationships with strategic partners in our supply chain have continued to serve the company and the group well in terms of security of supply and transparency around cost base increases across the goods and services we procure. “The company’s position as the world’s leading independent designer and supplier of track systems for armoured vehicles positions it well to take advantage of this increased demand. The company continues to invest in the development of new products for an ever-wider range of customers.” Earlier this year it was revealed how Cook Defence Systems had gone back to the history books as it tapped into its expertise to supply spares for up to 500 Ukrainian armoured vehicles. The tank track designer and manufacturer was awarded multiple contracts on behalf of the UK and the UK-administered International Fund for Ukraine (IFU), Defence Equipment & Support (DE&S) and part of the deal saw it reverse-engineer Soviet-era equipment for vehicles used by a large part of the Ukrainian Army.

Prima Cheese expands into London amid ambitions to grow overseas trade

Food firm Prima Cheese has expanded into London with a new office and retail space amid efforts to boost international trade. The County Durham dairy specialist, which specialises in shredded cheese for pizza toppings, has opened new premises in north London via its property company Prima Projects. 'Prima South' is located on Islington's Holloway Road in The Billiard Factory property which is home to a number of creative businesses and adjacent to the National Youth Theatre. It says the move is part of plans for growth in 2024, including pursuing more overseas trade opportunity. Prima already exports to 50 countries and in 2023 generated turnover of more than £18.7m outside of the UK. Read more: North East betting tech firm AceOdds snapped up in £36m deal by Danish group Read more: Electric powertrain specialist Saietta failed with deficit of £2.89m, administrators say Last year Prima featured for the fifth time in the North East's Fastest 50 list of fast-growing, privately owned businesses. It also reported "change and innovation" across the business as it invested amid a rise in turnover. In the year to March 31, 2023 it grew turnover by 32% to £121.7m. Over the same period, operating profit fell to £3.7m from more than £5m, though the firm grew its headcount slightly to 166. The acquisition of the Prima South space was advised by Sintons' partner Alok Loomba, partner, supported by Chris Jackson, senior associate. Mr Loomba, a long time advisor to Prima, said: "Prima Cheese was founded in 1996 and since then it’s grown to become one of the UK’s leading cheese processing businesses, exporting to countries around the globe. Prima’s is a real success story and the acquisition of this new site in London marks a significant milestone in its growth, opening doors to new markets in the UK and beyond.” Nagma Ebanks-Beni, co-CEO of Prima Cheese, said: "More than 25 years ago, Prima started operating out of a small industrial unit in County Durham; but we had big plans and today we’re one of the largest exporters in the North East. Our new London base is a key part of our growth strategy and Alok and his team moved quickly to help us secure the premises we wanted in what was a competitive and fast-moving environment."

Marvel-lous deal for mouthguard maker Safejawz

A Black Country sports equipment firm has struck a branding deal with huge US film and comic book brand Marvel. Aldridge-based Safejawz designs and makes mouthguards and is now selling products sporting designs depicting well known characters such as Captain America, Captain Marvel, Hulk and Spider-Man. The company was founded in 2014 by Ewan Jones and George Dyer who met at The University of Manchester and wanted to make sports mouthguards more fun and desirable. It now counts more than a million athletes and personalities as customers including England rugby player Joe Marler, Birmingham mixed martial artist Leon Edwards and YouTuber KSI. Email newsletters BusinessLive is your home for business news from across the West Midlands including Birmingham, the Black Country, Solihull, Coventry and Staffordshire. Click through here to sign up for our email newsletter and also view the broad range of other bulletins we offer including weekly sector-specific updates. We will also send out 'Breaking News' emails for any stories which must be seen right away. LinkedIn For all the latest stories, views and polls, follow our BusinessLive West Midlands LinkedIn page here. This latest tie up follows on from the company being awarded King's Award for Enterprise last month in recognition of its work to break into international markets. Mr Dyer said: "The Marvel Collection represents our brand ethos perfectly, allowing athletes of all levels to feel confident and bold, transforming a stereotypically known nuisance piece of kit into something you can wear with pride, that is both stylish and comfortable.

Humber modular building firm creates cells to solve prisons overcrowding

A Humber offsite construction firm has designed what it believes could solve the UK's prisons overcrowding crisis. Integra Buildings has designed and manufactured a custodial cell that has been tested at facilities at BRE Science Park in Watford to make sure it complies with Government standards. The Paull-based creator of modular buildings says the unit - which can function as a standalone space or stacked to make a building - is ready to be deployed at pace and could be the "silver bullet" to the prisons overcrowding crisis which has come to the fore in recent weeks. It is hoped the product could be used to quickly ramp up capacity and avoid some of the costs associated with renovating old, sometimes Victorian, prison buildings and building entirely new facilities. Integra is also marketing it as a solution for other detention settings in the criminal justice system. The unit has been developed for Category C prisoners who make up a large proportion of the UK prison population and while considered unlikely to make escape attempts are not trusted in open prisons. The firm said it uses a concrete base and composite materials, to make a robust, non-combustible cell which is compliant with what is referred to as “breach and ligature criteria”. It can be built to a variety of sizes, with the smallest cell measuring 2.6m x 3m, and includes a shower, toilet and washbasin. Chris Turner, managing director of East Yorkshire-based Integra, said: “Prisons overcrowding is without doubt an issue of significant public concern and a major priority for the new Government. We believe modular construction can and should play an important part in addressing this issue. "Our unit is ready to be manufactured and rolled out right now. Modular construction has numerous advantages over traditional building methods and we have a bespoke, fully-tested unit which can help tackle the prisons overcrowding crisis, as well as being deployed in other custodial settings.”

North East Mayor to approve investment into £14.6m manufacturing skills facility

A £14.6m investment is set to be made into a new project aiming to drive forward a new generation of skilled local workers in electric vehicle and battery technology. North East Mayor Kim McGuinness and local authority leaders at the North East Combined Authority are set to approve the landmark skills investment into MADE NE – Manufacturing, Automation, Digitalisation, Electrification North East – a project poised to be led by car giant Nissan with a mission to create world-leading training facilities across two sites at the International Advanced Manufacturing Strategic Site (IAMSS) in Sunderland. MADE NE is the first project to come forward as part of the region’s Investment Zone – a £160m, 10-year programme expected to create at least 4,000 jobs and secure £3bn of private sector investment – and a report to the Mayor and Cabinet recommends the project receives £9.7m from the Combined Authority. The multimillion-pound facility will provide facilities to industry for skills training within the region’s advanced manufacturing sector, with a special focus on EV and battery manufacturing, covering the development of skills from primary school to apprenticeships, as well as including in-work learning and training. The centre aims to support targeted industrial innovation projects with funding and equipment, and also aims to be self-sustaining in five years, generating revenue linked with the delivery of apprenticeships as well as through sub-letting space to businesses. The plan has been developed in partnership by Nissan with the Combined Authority, Sunderland City Council, Education Partnership North East (EPNE), New College Durham, AESC, Vantec, Newcastle University, the Offshore Renewable Energy Catapult, and the North East Automotive Alliance (NEAA). Plans for MADE NE will go before the North East Combined Authority Cabinet at its meeting next Tuesday, July 30. North East Mayor Kim McGuinness said: “In my manifesto I promised to back our world-leading automotive industry. Now we are delivering. This investment will unlock a generation of skilled workers and create opportunities for local people and businesses. “It cements our reputation as a global success story in advanced manufacturing and shows how we can lead the industries of the future. The investment shows how we can make the North East the home of real opportunity by backing local workers and businesses – so our area has good, well-paid, high-skilled jobs and training on the doorstep.“ Adam Pennick, vice president, manufacturing, at Nissan Sunderland Plant, said: “To build the cars of the future, you need the skills of the future. This fantastic new facility will help find the talent, nurture the technical skills and drive the spirit of innovation that will power advanced automotive manufacturing in the UK. Nissan Sunderland is proud of its track record on skills development and we know that to deliver our EV36Zero vision we need to do more. “That’s why we are excited to be leading this collaborative long-term project to take skills development to the next level, for the benefit of the North East of England.” Coun Michael Mordey, Cabinet member for Finance and Investment and Leader of Sunderland City Council, said: “We are proud that Sunderland is the beating heart of the most important economic motor this region has, and that – in securing this investment – we can continue to drive its success with talented, highly-skilled people, trained in the city and able to contribute to the success of this whole region. And indeed to ensure that the supply chain is developed with the availability of a world-class workforce.